Aleppo soaps

24 products

Showing 1 - 24 of 24 products

The story of the first Syrian soap

Aleppo natural soap is produced in the Syrian city of the same name. The tradition of soapmaking dates back to 1500 BC, when the Phoenicians produced it in what is now Syria. For 2,000 years, the soap has been handcrafted by the city's residents, and today it has become known worldwide.

Despite the passage of time, it's still made according to an ancient recipe—based on olive oil and bay laurel oil. It's likely one of the first cleansing agents, the first soap. The recipe is timeless for a reason.

Properties of soap with laurel oil

Aleppo soap undoubtedly owes its popularity to its nourishing properties. One of its key ingredients, bay laurel oil , plays a key role. It is derived from the bay laurel tree, also known as the bay laurel, and has strong antiseptic properties. It has been successfully used in folk medicine.

The properties of laurel oil in Aleppo soaps are used to cleanse skin, especially problematic skin. It disinfects, cleanses, destroys bacteria and fungi, and soothes inflammation. It is recommended as a supportive treatment for acne, psoriasis, dandruff, and atopic dermatitis. It regulates sebum secretion and unclogs pores, restoring the skin's healthy appearance. Furthermore, Syrian soap accelerates the healing of wounds and inflammation, and moisturizes, nourishes, and softens the skin.

Which Aleppo soap should I choose?

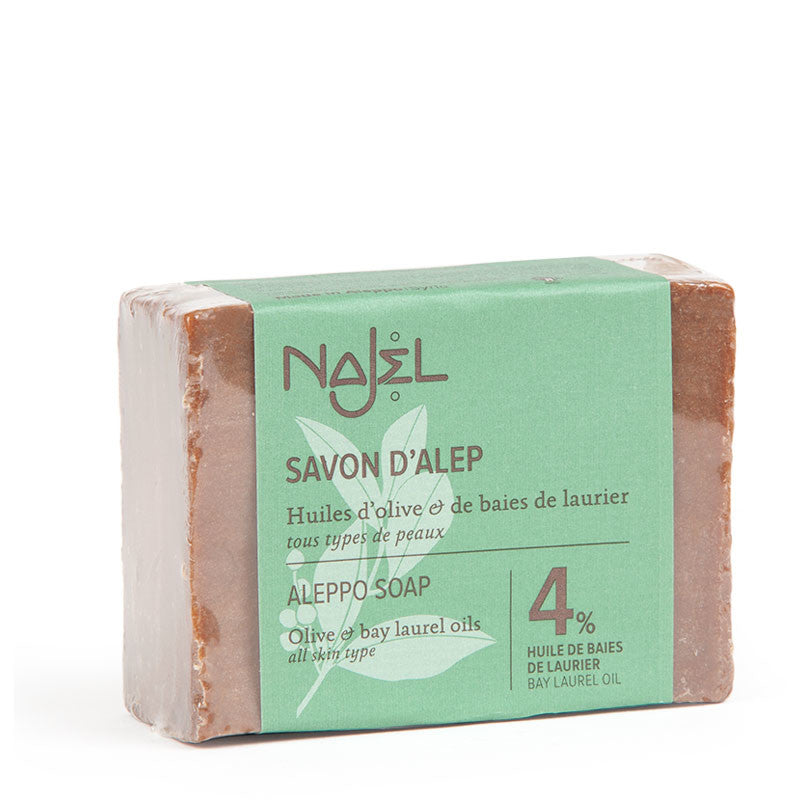

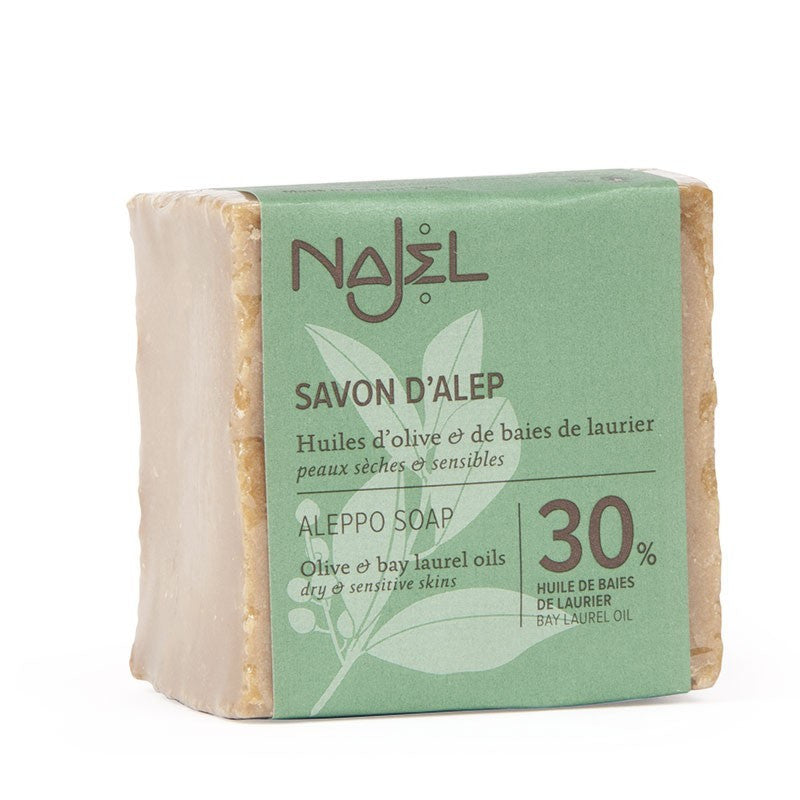

Authentic Aleppo soaps have been made from the same ingredients for hundreds of years, and each type is distinguished by the proportions of laurel oil and olive oil. Soaps with a small amount of laurel oil are gentle and ideal for regular daily cleansing. The more oil, the stronger the healing effect.

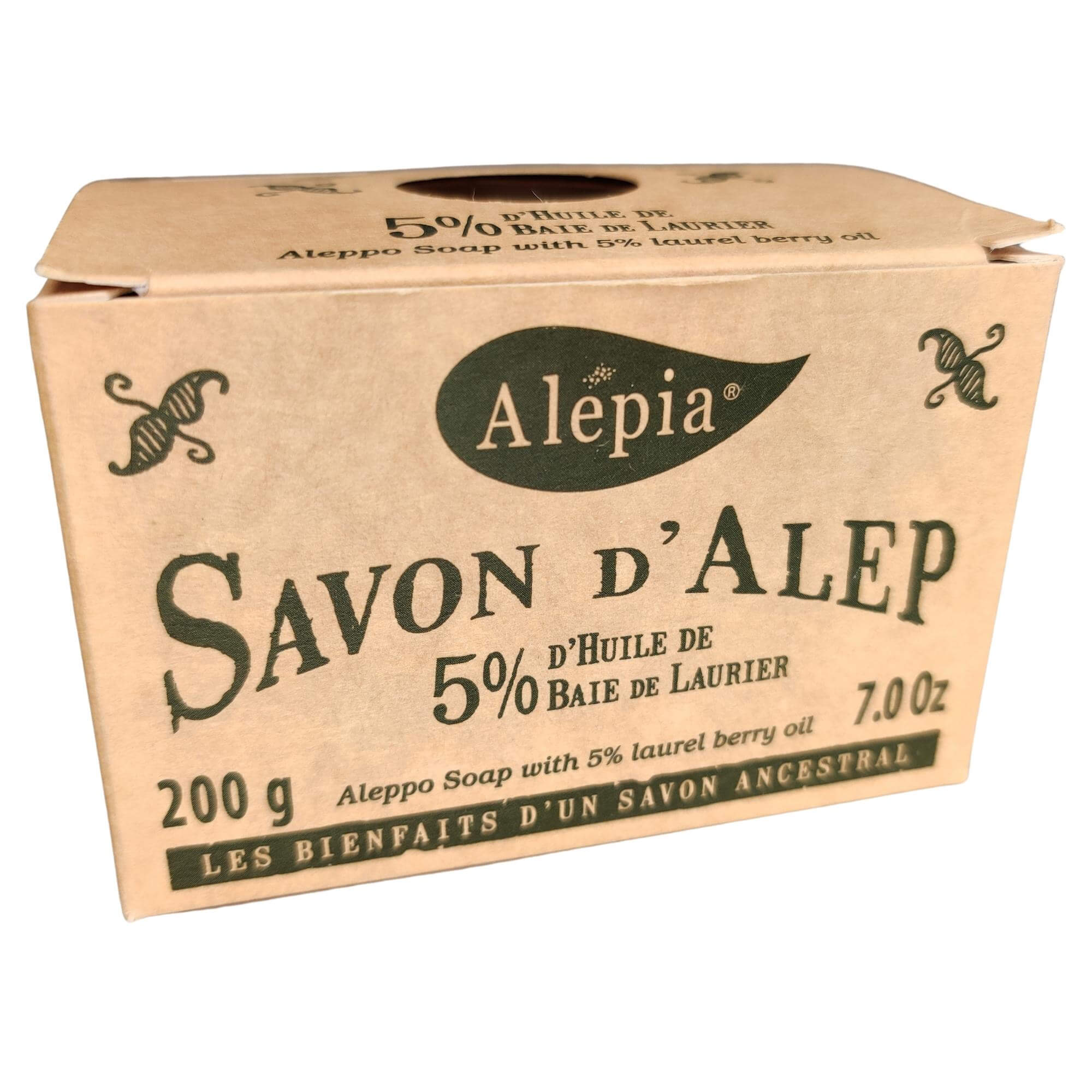

- Aleppo Soap with 5% Laurel Oil – intended for daily care, for normal, sensitive, and dry skin. It moisturizes well, but may not be effective in treating more serious skin conditions. Recommended use: once daily.

- Aleppo soap with 12-15% laurel oil is slightly stronger, but still gentle. It can help treat mild inflammation and skin conditions. Can be used regularly, preferably once a day.

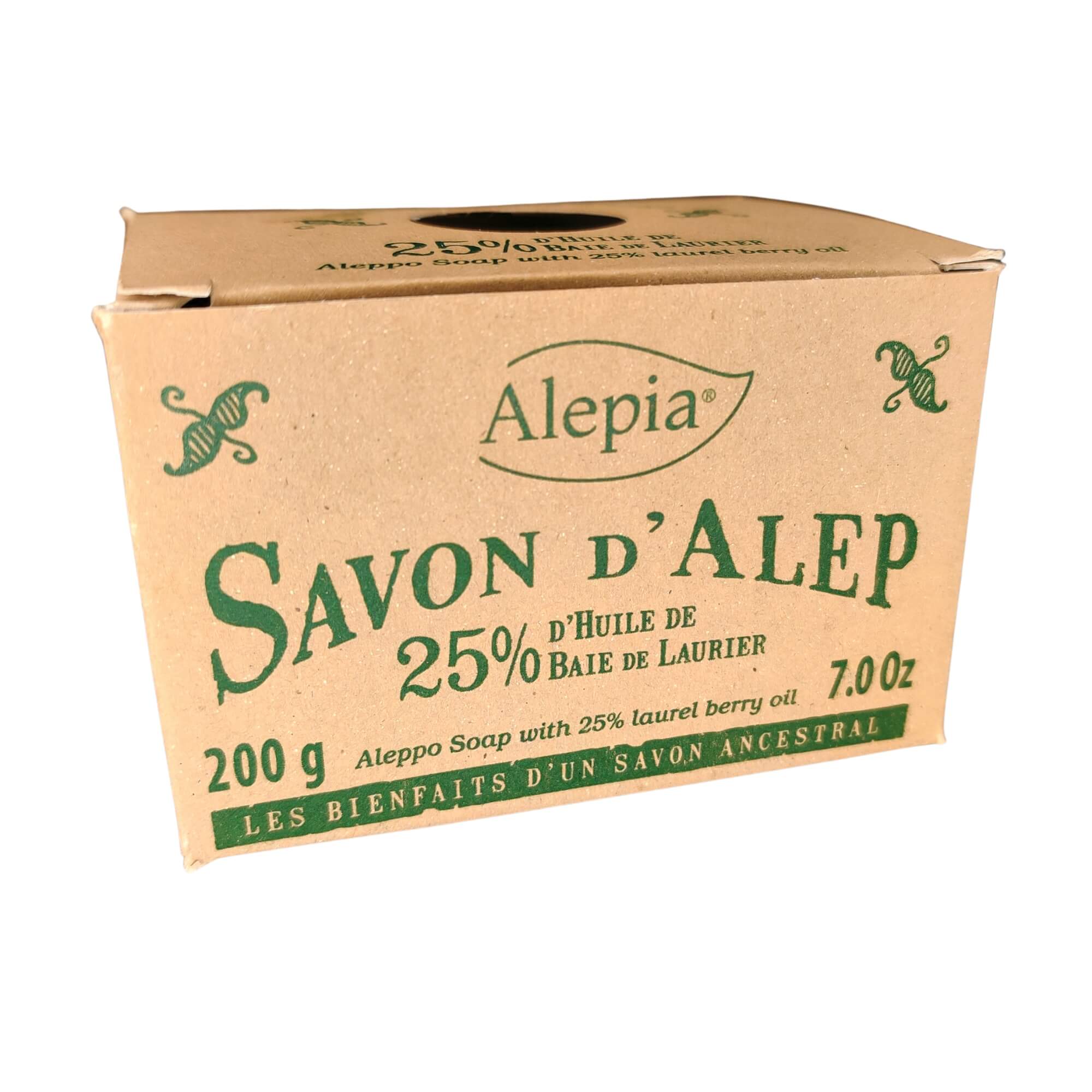

- Aleppo soap with 20-30% laurel oil is balanced and can effectively combat skin problems. Recommended for those with normal, oily, and acne-prone skin. Use no more than once a day.

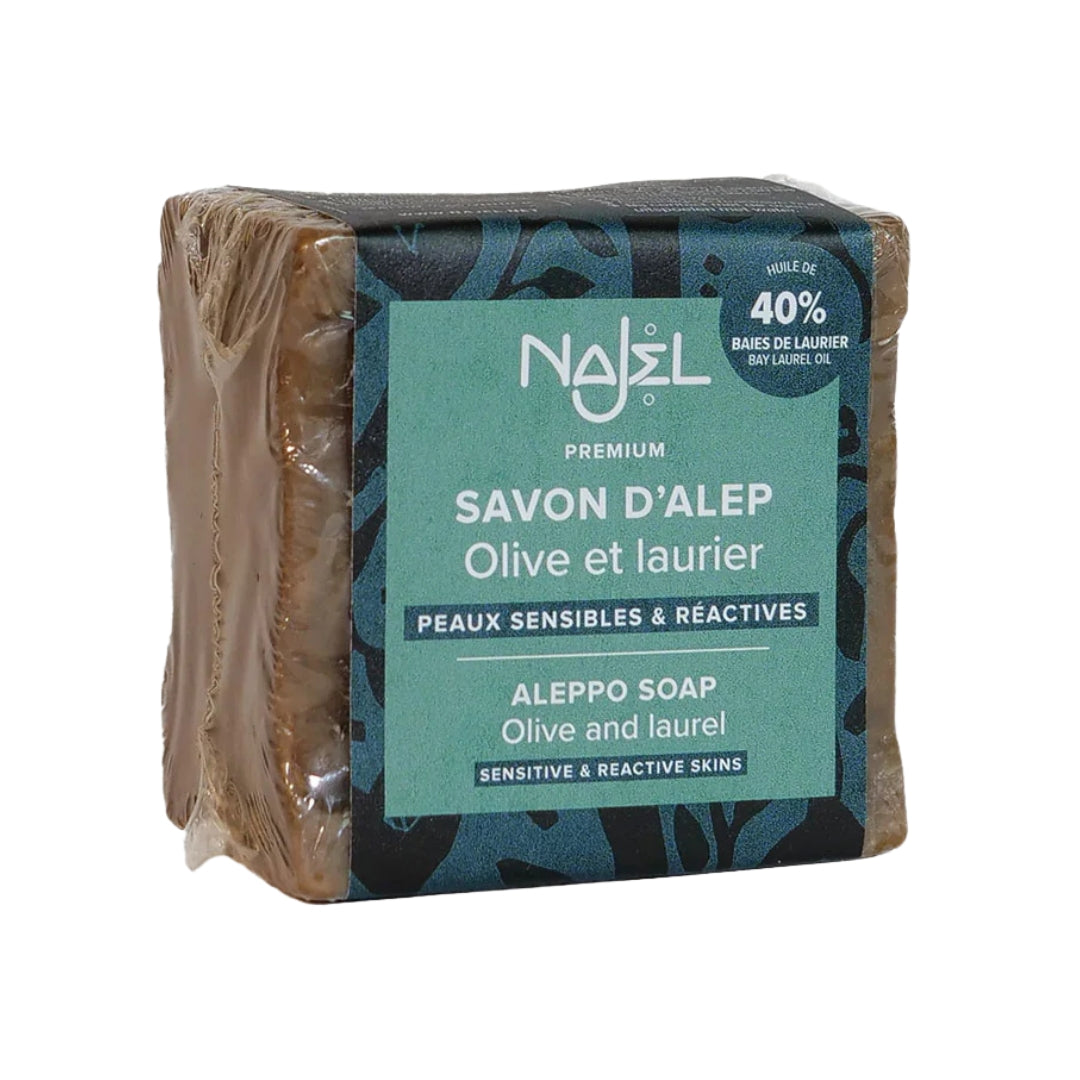

- Aleppo soap with 40-55% laurel oil has a strong healing effect, designed to combat more advanced skin conditions. It does not have the same moisturizing properties as soaps with higher olive oil content. It is recommended to use it periodically, only during treatment. The soap should not be used more than once a day.

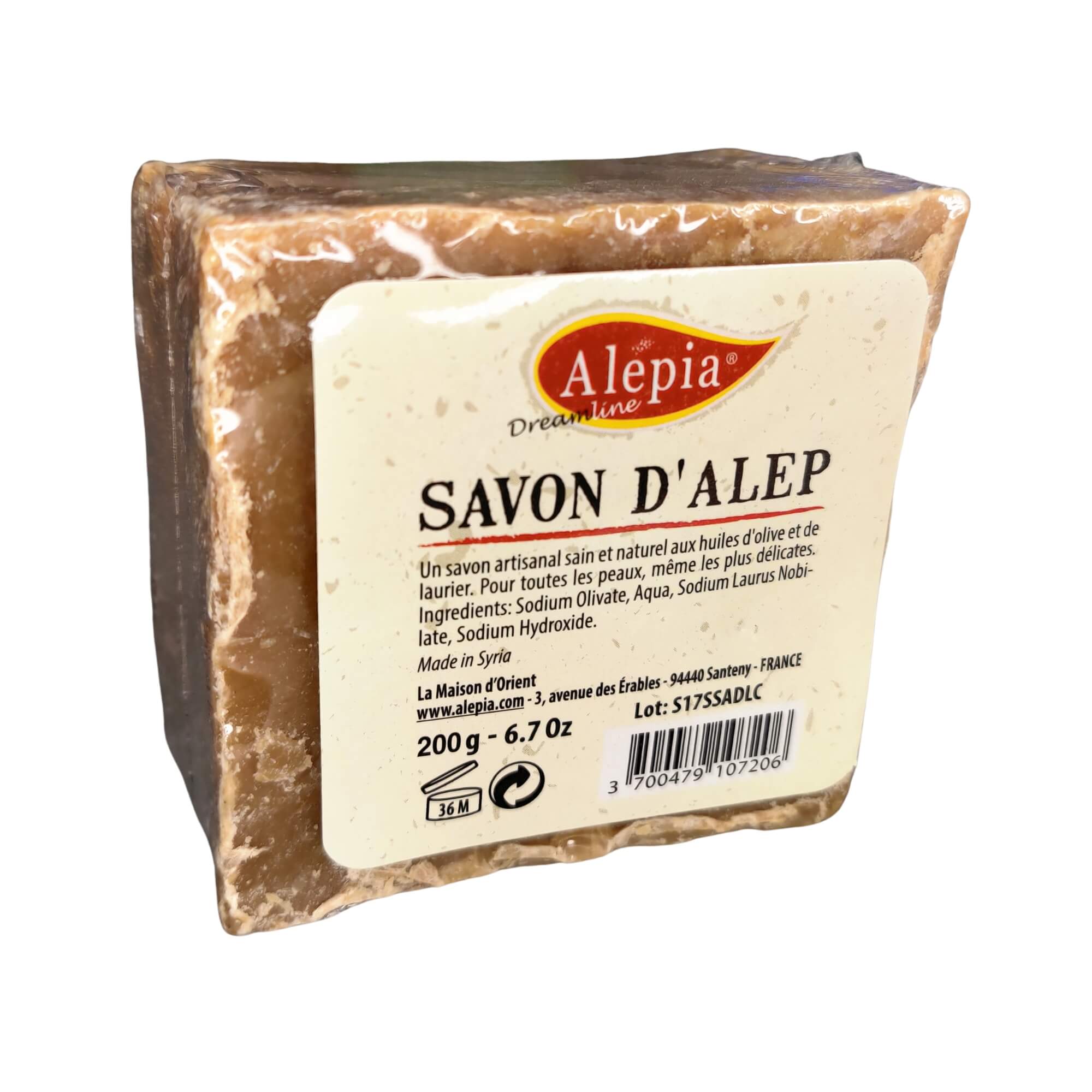

Original Aleppo soaps are made from four ingredients: olive oil, bay laurel oil, water, and sodium. These 100% natural ingredients rarely cause allergies or negative skin reactions. However, it's important to remember not to overuse this type of soap. Excessive use can dry out the skin.

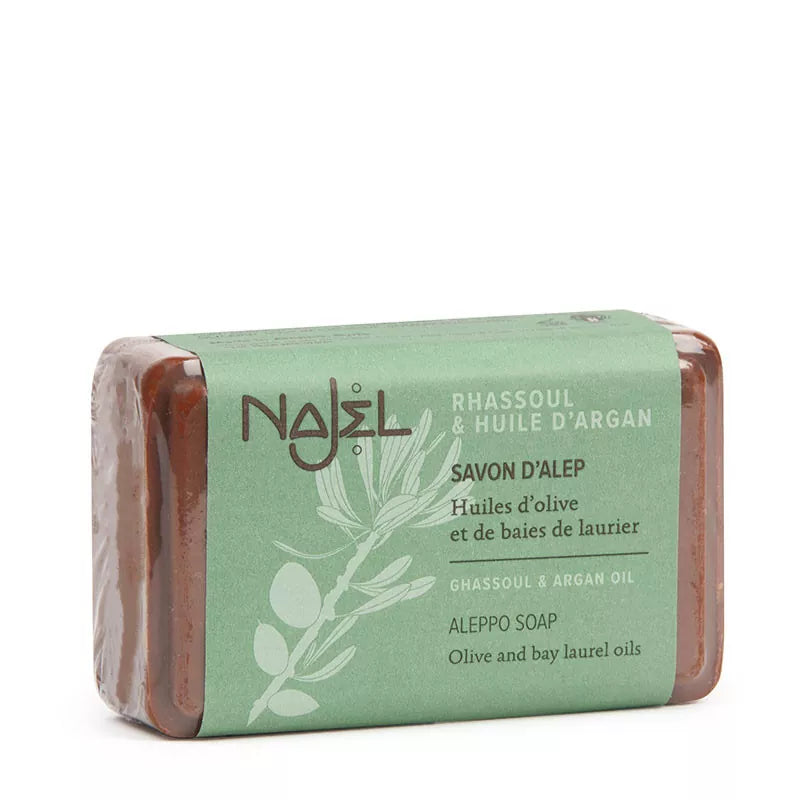

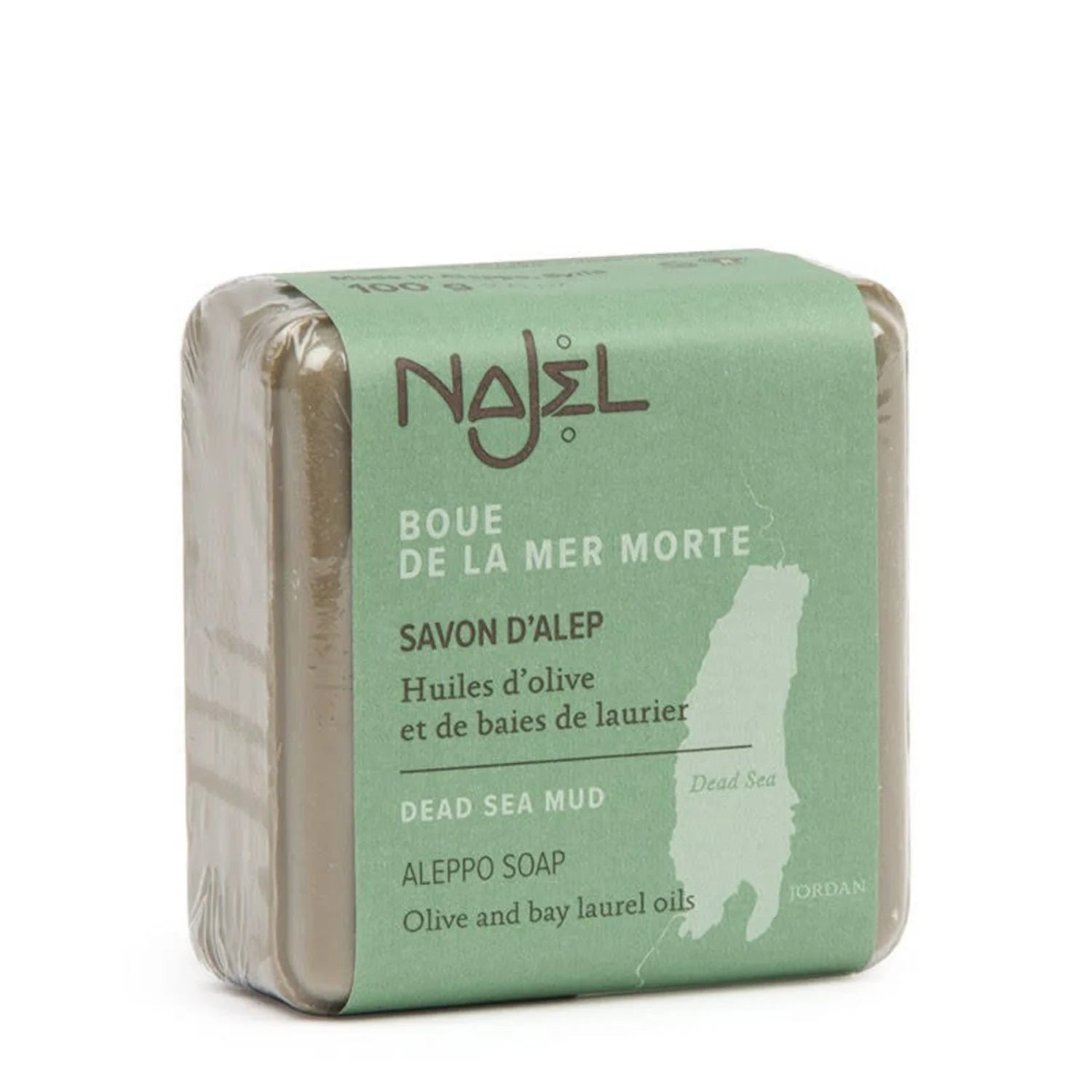

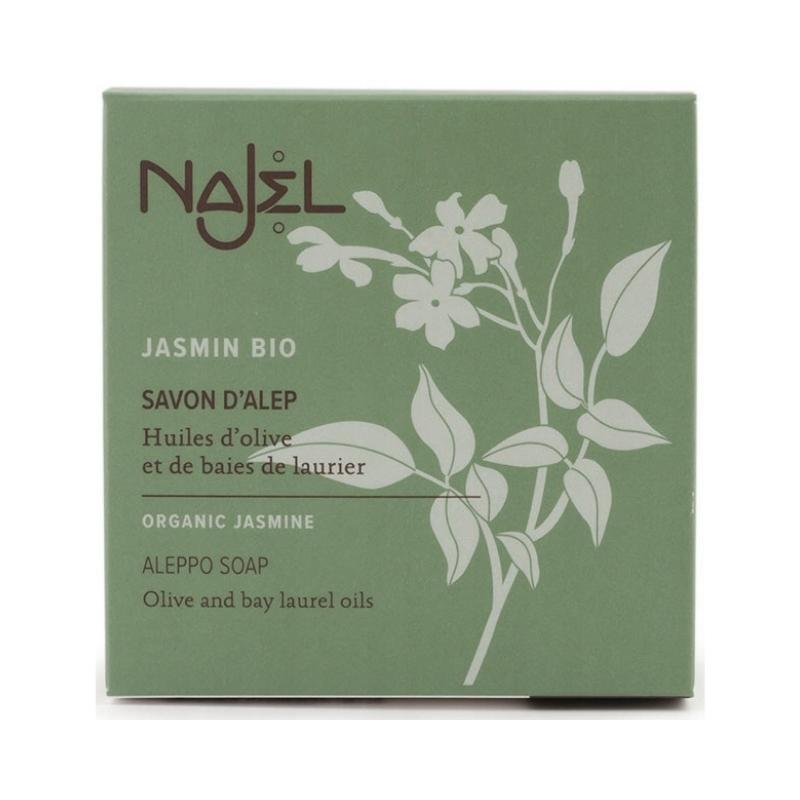

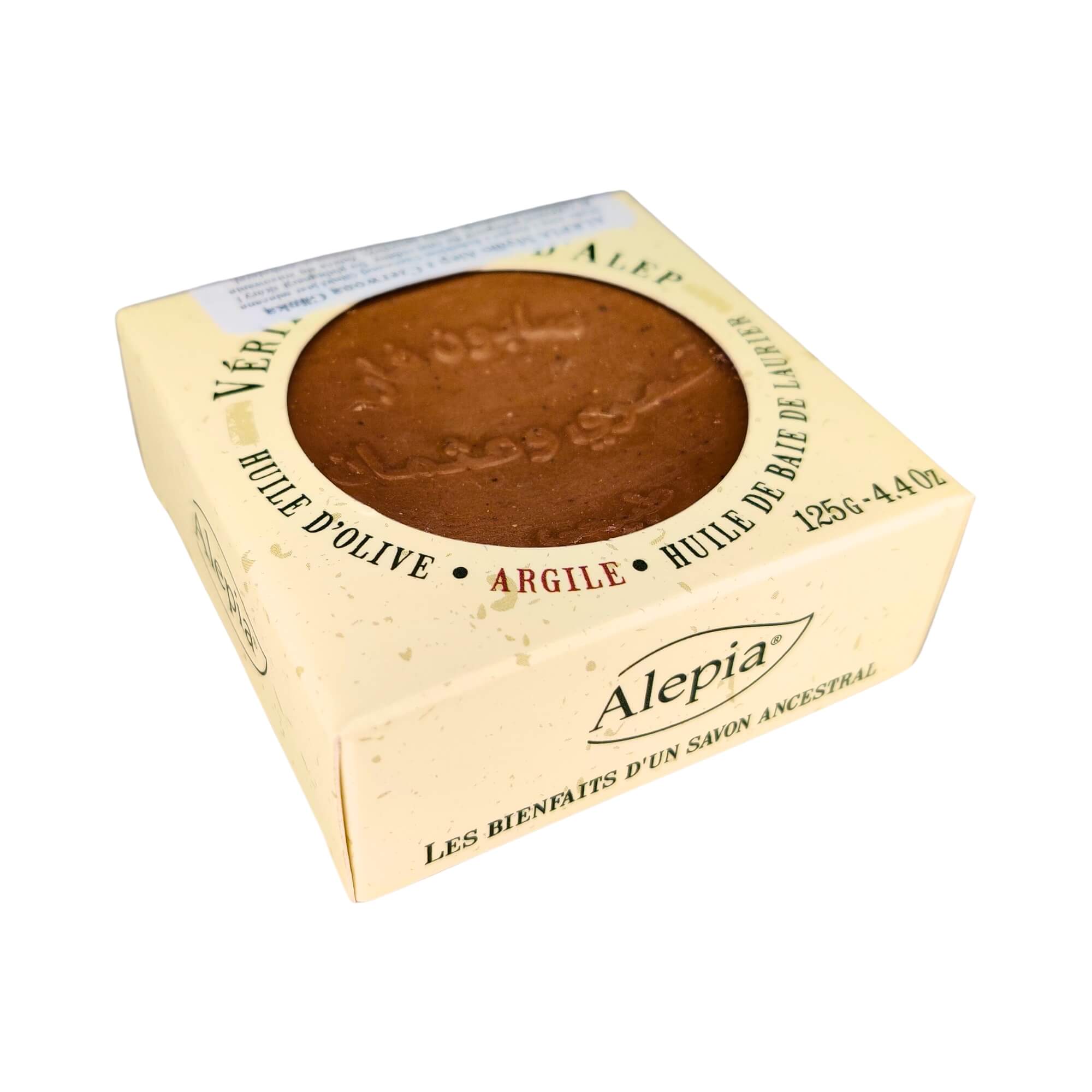

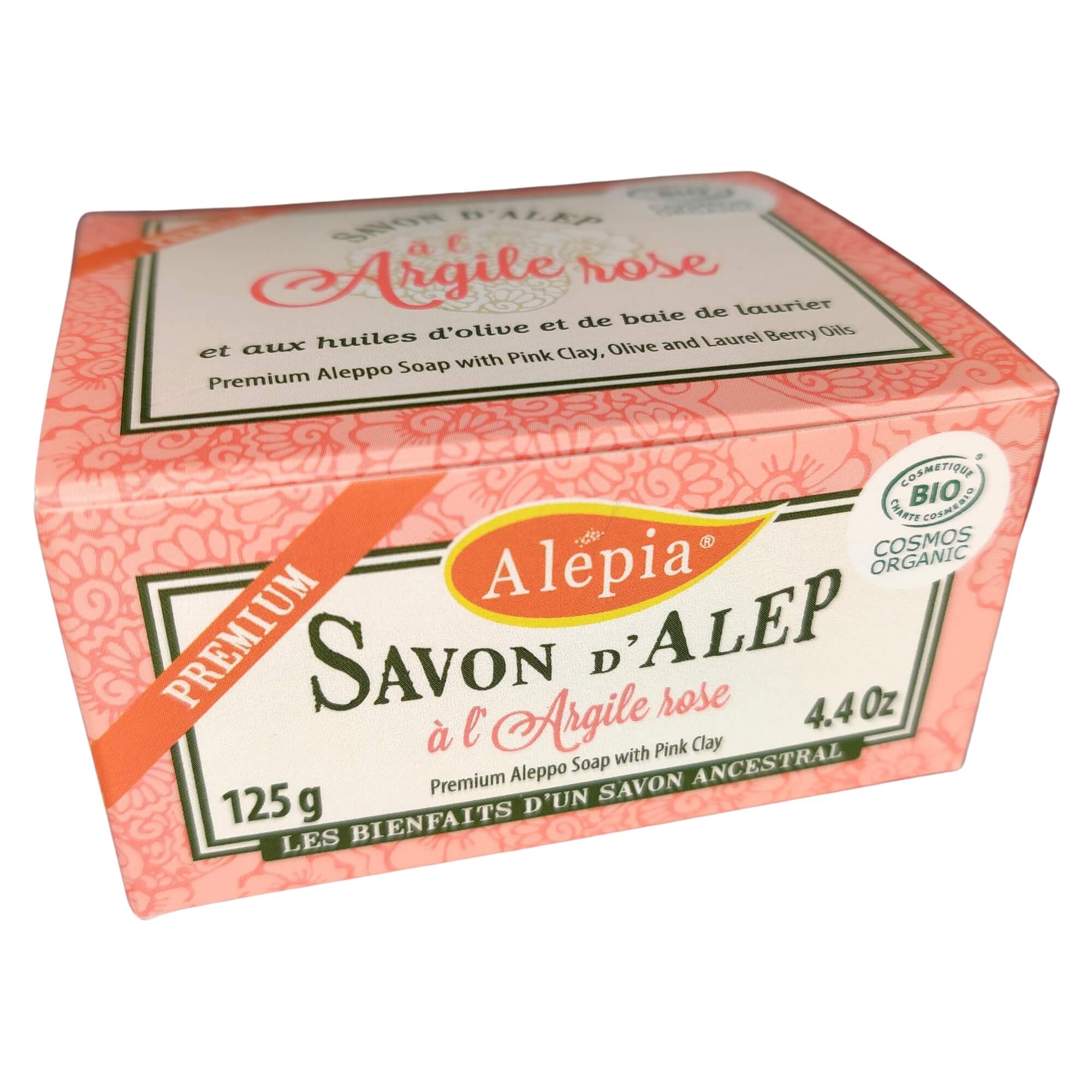

Aleppo soaps are also being created with additives such as black cumin oil , rose, and jasmine, which can aid healing. This is also an interesting option for those who would like to diversify their skincare routine and leave the skin with the scent of rose, jasmine, or oud. And for those who value convenience, we recommend Aleppo liquid soaps .

How are Aleppo soaps made?

Traditional Aleppo soaps are handmade and their production process includes several stages:

- Aleppo soap production is seasonal, typically lasting from November to March. The first step is to heat water and sodium hydroxide to a specific temperature in a large cauldron. Olive oil is then added and left at a high temperature for 12 hours.

- After waiting, the mass is heated again in the cauldron and previously filtered laurel oil is added.

- The resulting soap paste is rinsed several times with salted water to remove all traces of caustic substances and impurities. The water is then drained from the boiler, and the oil is transformed into soap molecules through a natural chemical reaction between the oils and sodium hydroxide.

- The resulting soap mass is spread into molds and smoothed. Once set, it is ready to be hand-cut into cubes and stamped.

- The cut soap bars are placed on pallets in darkened cellars, where they begin a months-long drying process. During this time, the soaps oxidize on the surface, turning yellow-brown while retaining their olive-green color inside.

- Once drying is complete, the Aleppo soap bars are packed into boxes and shipped to customers.