Najel

12 products

Showing 1 - 12 of 12 products

About the company Najel

Najel , a brand run by the Najjar Laboratory, has specialized in producing organic cosmetic products made with olive oil and bay laurel oil for over twenty-five years. Najel is particularly known for its Aleppo soap , the ancestor of Marseille soap.

The Al Najjar family has been producing soaps at their Aleppo factory since 1895, using traditional recipes passed down through generations. Today, the company has its headquarters and laboratory in France. However, authentic Aleppo soap can only be made in Aleppo and its surrounding region, so Najel soaps are produced seasonally at the factory in Syria. Their extensive experience allows them to produce natural, organic, and top-quality Syrian cosmetics.

Aleppo soap by Najel

The name "Aleppo soap" itself is legally protected, and any product bearing this name must be produced in Aleppo. Products labeled "bay soap" are most often produced in other regions of Syria, but this does not mean they are of lower quality—they simply cannot be called genuine Aleppo products.

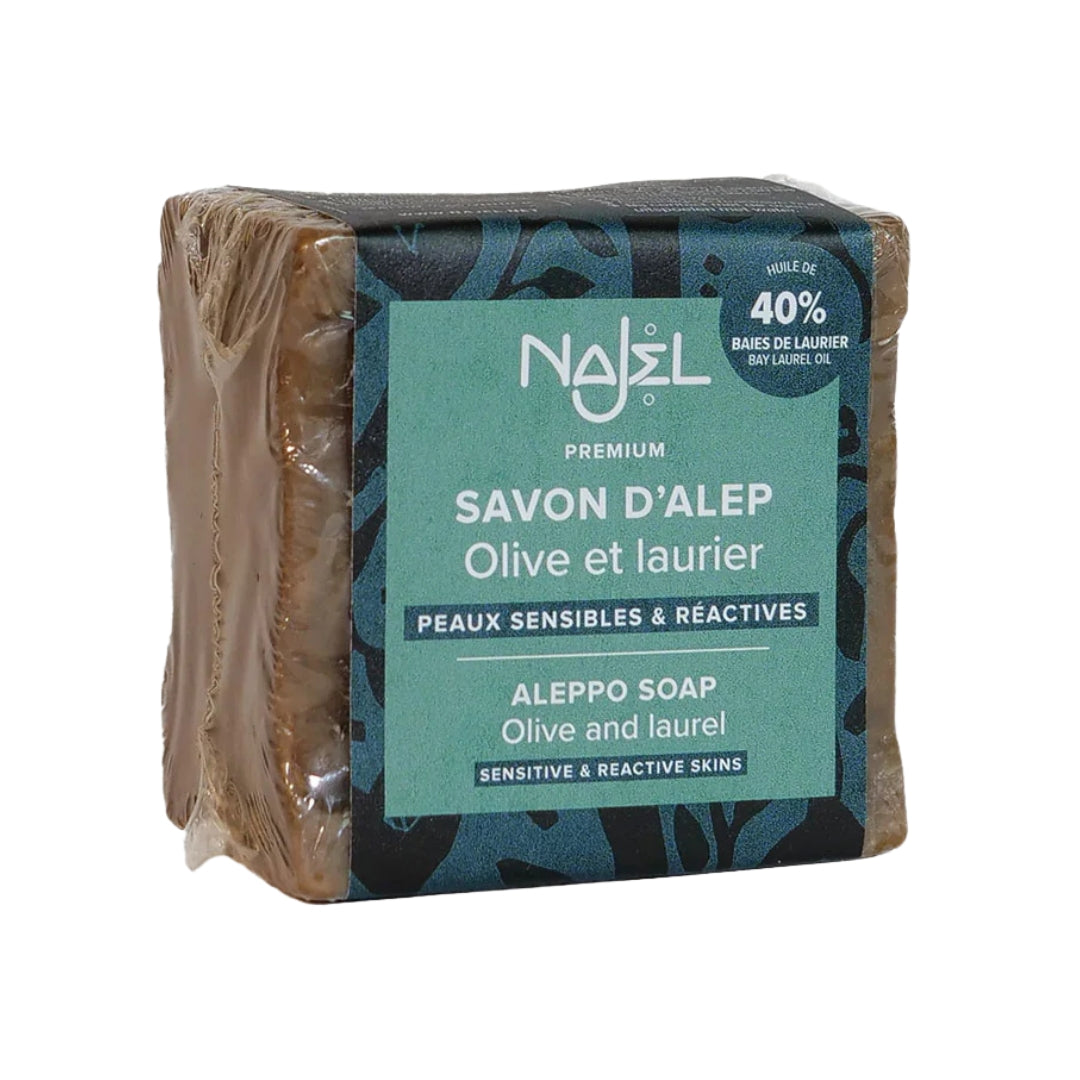

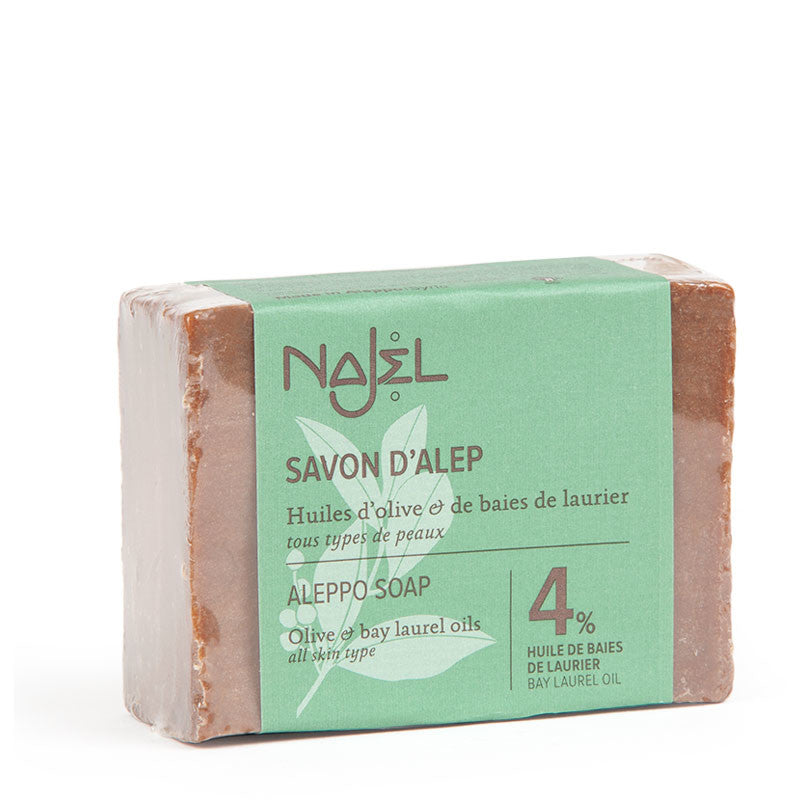

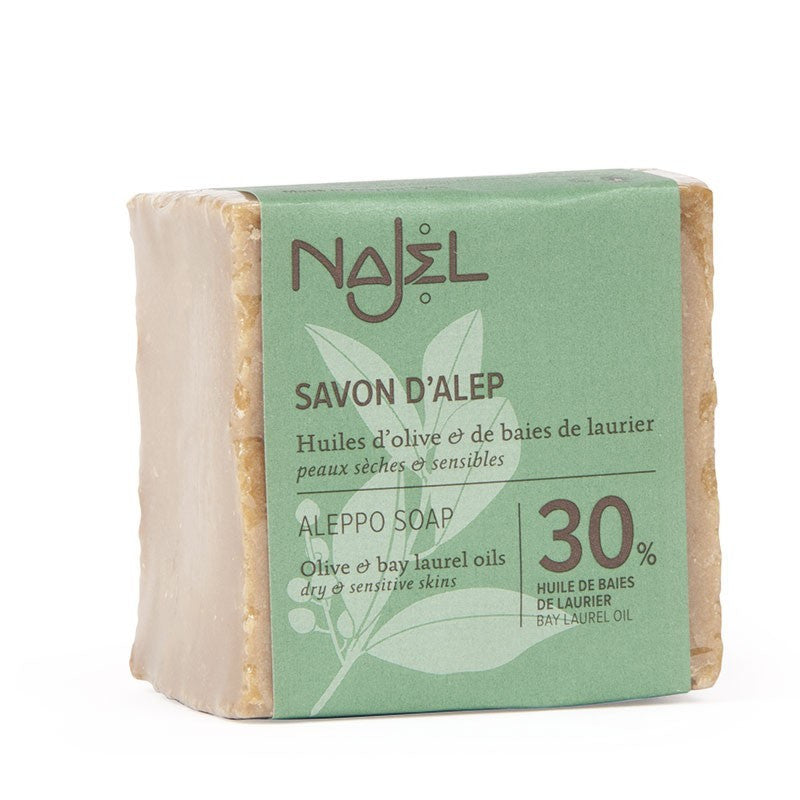

The soap's primary ingredients are olive oil and bay laurel oil . It's the bay laurel oil that provides its healing properties. It has strong antibacterial and antifungal properties. Soaps with higher concentrations of bay laurel oil help combat skin conditions such as acne, psoriasis, and atopic dermatitis, disinfect, and promote wound healing. Gentler soaps with lower concentrations are recommended for daily care.

Najel produces soaps in Aleppo according to a traditional recipe. Production of this type of soap is seasonal, lasting from November to March. It involves several stages:

- The process begins by heating water and sodium hydroxide to a specific temperature in a large pot. Olive oil is then added and left at a high temperature for 12 hours.

- The next day, the contents of the cauldron are heated and filtered laurel oil is added.

- The soap paste is rinsed repeatedly with salted water to remove any impurities and corrosive substances.

- The soap paste is then spread into molds and smoothed. Once it hardens, it is cut into cubes and marked with a stamp.

- The soap bars are placed on pallets and begin a 9-month drying period in darkened basements.

- Once drying is complete, the Aleppo soap bars are packaged and can be shipped to customers.